Introduction: The Importance of Potato Drying

Potatoes, a globally cherished staple crop, are rich in nutrients and widely used in snacks, processed foods, and culinary applications. Proper drying is critical to preserving their flavor, texture, and nutritional value while extending shelf life. Traditional drying methods, such as sun-drying or coal-fired drying, often struggle with inconsistent temperature control, high energy consumption, and contamination risks. In contrast, MeiYa Air Source Heat Pump Dryers offer a modern, efficient, and sustainable solution tailored for industrial-scale potato processing.

Why Choose MeiYa Heat Pump Dryers?

MeiYa’s cutting-edge technology ensures optimal drying results while addressing the shortcomings of conventional methods:

- Energy Efficiency: Consumes 60-70% less energy than traditional dryers, significantly reducing operational costs.

- Precise Temperature Control: Maintains uniform heat distribution for consistent product quality.

- Automated Operation: Minimizes manual intervention with programmable settings for multi-stage drying.

- Eco-Friendly: Zero emissions and low noise, aligning with green manufacturing standards.

- Hygienic Design: Closed-loop drying system prevents contamination and ensures food safety.

Step-by-Step Potato Drying Process with MeiYa Dryers

1. Preparation

- Selection & Peeling: Use fresh, unblemished potatoes. Peel manually or via chemical methods for large-scale operations. Remove eyes and imperfections.

- Slicing: Cut into uniform 3.5–5 mm slices using industrial slicers. Immerse slices in water to prevent oxidation.

2. Blanching

- Blanch slices in 85–95°C water for 1–2 minutes to deactivate enzymes and preserve color.

- Cool immediately in clean water and drain excess moisture.

3. Multi-Stage Heat Pump Drying

- Stage 1: Color Fixation (40°C)

Arrange slices evenly on trays and load into the MeiYa dryer. Start with a low temperature (40°C) to lock in natural color and prevent browning. - Stage 2: Main Drying (60–70°C)

Gradually increase temperature to 60–70°C for efficient moisture removal. MeiYa’s smart humidity sensors adjust airflow to ensure uniform drying without over-drying edges. - Final Moisture Content: Dry until slices reach ≤10% moisture for crisp texture and long-term storage stability.

Traditional vs. MeiYa Heat Pump Drying: Key Differences

| Factor | Traditional Methods | MeiYa Heat Pump Dryer |

|---|---|---|

| Temperature Control | Inconsistent, risk of scorching | Precise, adjustable multi-stage settings |

| Energy Use | High (coal/electric resistance) | Ultra-low (heat recovery technology) |

| Labor Dependency | High (manual monitoring) | Fully automated with remote control |

| Product Consistency | Variable quality | Uniform drying, premium output |

Conclusion: Elevate Your Potato Processing with MeiYa

MeiYa Air Source Heat Pump Dryers revolutionize potato drying by combining precision, sustainability, and cost-effectiveness. Whether producing potato chips, dehydrated snacks, or ingredients, our technology guarantees superior quality while slashing energy bills and carbon footprints.

Contact us today to customize your potato drying solution!

📧 Email: [email protected]

📞 Contact: Ray Ren

📱 WhatsApp/WeChat/Mobile: +86 133 4676 7871

MeiYa – Innovating Drying, Empowering Industry.

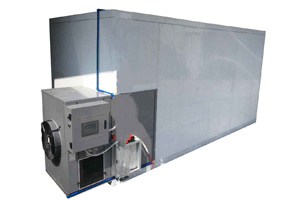

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com