Introduction: The Importance of Proper Garlic Drying

Garlic, a globally cherished ingredient, requires precise drying to preserve its flavor, nutritional value, and shelf life. Improper drying can lead to mold growth, discoloration, or loss of essential oils, resulting in significant economic losses. Traditional drying methods—such as sun drying or conventional hot-air systems—often struggle with inconsistent temperature control, high energy consumption, and labor-intensive processes. MeiYa Air Source Heat Pump Dryers revolutionize this process by combining intelligent temperature management, energy efficiency, and automated operation to deliver superior drying results.

Why Choose MeiYa Heat Pump Dryer for Garlic?

- Energy Efficiency & Cost Savings

MeiYa’s technology recovers latent heat from moisture removal, reducing energy consumption by up to 70% compared to traditional dryers. - Precision Temperature & Humidity Control

Multi-stage programming ensures optimal conditions for garlic, minimizing quality degradation. - Odor Management

Integrated dehumidification and air filtration systems effectively neutralize pungent garlic odors during drying. - Low Maintenance & Automation

Minimal manual intervention required; the system auto-adjusts parameters for uninterrupted operation.

MeiYa’s 4-Stage Garlic Drying Process

Based on Proven Industrial Parameters

Stage 1: Pre-Heating (1 Hour)

- Target Temperature: 50°C

- Purpose: Gentle heating to initiate moisture release without thermal shock.

- Note: In colder environments (ambient <20°C), MeiYa’s auxiliary electric heating ensures rapid temperature stabilization.

Stage 2: Intensive Dehydration (3 Hours)

- Temperature: 55°C

- Action: Continuous dehumidification removes surface moisture and activates internal water migration.

Stage 3: Deep Drying (4 Hours)

- Temperature: 60°C

- Humidity Control: Maintains 20% RH to prevent overdrying while ensuring uniform texture.

Stage 4: Final Conditioning (2 Hours)

- Target Moisture: 15% (industry-standard for safe storage and packaging).

- Result: Preserved color, flavor, and antimicrobial properties with no cracking or brittleness.

Traditional vs. MeiYa Heat Pump Drying

| Factor | Traditional Methods | MeiYa Heat Pump Dryer |

|---|---|---|

| Energy Use | High (fuel/electricity) | Ultra-low (heat recovery technology) |

| Temperature Stability | Fluctuates with ambient conditions | ±1°C precision via PID control |

| Labor Demand | Constant monitoring required | Fully automated with remote monitoring |

| Environmental Impact | High emissions | Eco-friendly (zero direct emissions) |

Conclusion

MeiYa Air Source Heat Pump Dryers set a new benchmark for garlic drying, blending advanced technology with operational simplicity. By ensuring consistent quality, reducing energy costs, and addressing odor challenges, MeiYa empowers producers to meet global market demands efficiently.

Contact Us Today to Optimize Your Garlic Drying Process!

- Email: [email protected]

- Contact Person: Ray Ren

- WhatsApp/WeChat/Mobile: +86 133 4676 7871

MeiYa – Innovating Drying Solutions for a Sustainable Future.

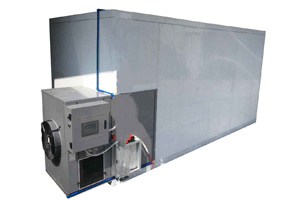

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com