Introduction: The Importance of Proper Mushroom Drying

Mushroom drying is a critical process to preserve flavor, texture, and nutritional value while extending shelf life. Improper drying can lead to color degradation, loss of aroma, or microbial growth. Traditional methods, such as sun-drying or coal-fired dehydration, often result in uneven drying, high energy consumption, and inconsistent quality. In contrast, modern heat pump technology offers a sustainable, precise, and efficient alternative. MeiYa Air-Source Heat Pump Dryers are engineered to deliver superior results, ensuring premium-quality dried mushrooms with minimal operational costs.

Advantages of MeiYa Heat Pump Drying Technology

MeiYa’s advanced drying systems outperform traditional methods through:

- Energy Efficiency: Reduce energy consumption by up to 70% compared to conventional dryers.

- Precision Control: Maintain stable temperatures (±1°C accuracy) and automated humidity management.

- Uniform Drying: Even airflow distribution eliminates hot/cold spots for consistent product quality.

- Low Labor Dependency: Fully programmable operations minimize manual intervention.

- Eco-Friendly: Zero emissions and compliance with global sustainability standards.

Step-by-Step Mushroom Drying Process with MeiYa Dryers

1. Loading & Preparation

- Tray Arrangement: Place mushrooms in perforated trays, ensuring proper airflow. Position thicker, high-moisture varieties (e.g., portobello) on upper racks and thinner types (e.g., shiitake) on lower racks. Maintain 30 cm spacing between trays (max 10 layers) to optimize heat distribution.

- Initial Setup: Preheat the dryer to 35°C before loading to prevent condensation and ensure a gentle start.

2. Temperature Control Phases

- Phase 1 (35–40°C, 6 hours): Slow drying to preserve enzymatic activity and prevent surface hardening.

- Phase 2 (40–60°C, 8 hours): Gradually increase heat by 1–3°C/hour to evaporate internal moisture without cracking or shrinking.

- Phase 3 (80–85°C, 2 hours): Final high-temperature stage ensures sterilization and reduces residual moisture to ≤13%.

Note: Avoid abrupt temperature spikes, which can cause cracking, discoloration, or loss of natural fragrance.

3. Humidity Management

- Early Stage: Slow dehumidification at 35–40°C to prevent over-drying.

- Mid-Stage: Intermittent dehumidification at 40–60°C balances moisture removal and color retention.

- Final Stage: Disable dehumidification above 60°C to avoid brittleness and maintain golden-yellow gills.

MeiYa’s intelligent system auto-adjusts humidity levels, preventing under-drying (waterlogged appearance) or over-drying (bleached texture).

4. Quality Inspection

After 16–18 hours, verify dryness by pressing the cap-stem junction:

- Optimal Result: Slight indentation with no softness; intact, upright gills; earthy aroma.

- Under-Dried: Re-dry at 60°C for 1–2 hours if the stem feels flexible.

Conclusion: Why Choose MeiYa?

MeiYa Heat Pump Dryers revolutionize mushroom processing by combining precision, efficiency, and scalability. Whether drying delicate enoki or robust oyster mushrooms, our technology ensures uniform results, superior sensory quality, and compliance with international food safety standards.

Upgrade to MeiYa’s sustainable drying solutions and transform your production efficiency today!

Contact Us for Customized Drying Solutions

📧 Email: [email protected]

📞 Contact: Ray Ren

📱 WhatsApp/WeChat/Mobile: +86 133 4676 7871

MeiYa – Innovating Quality, Preserving Nature.

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

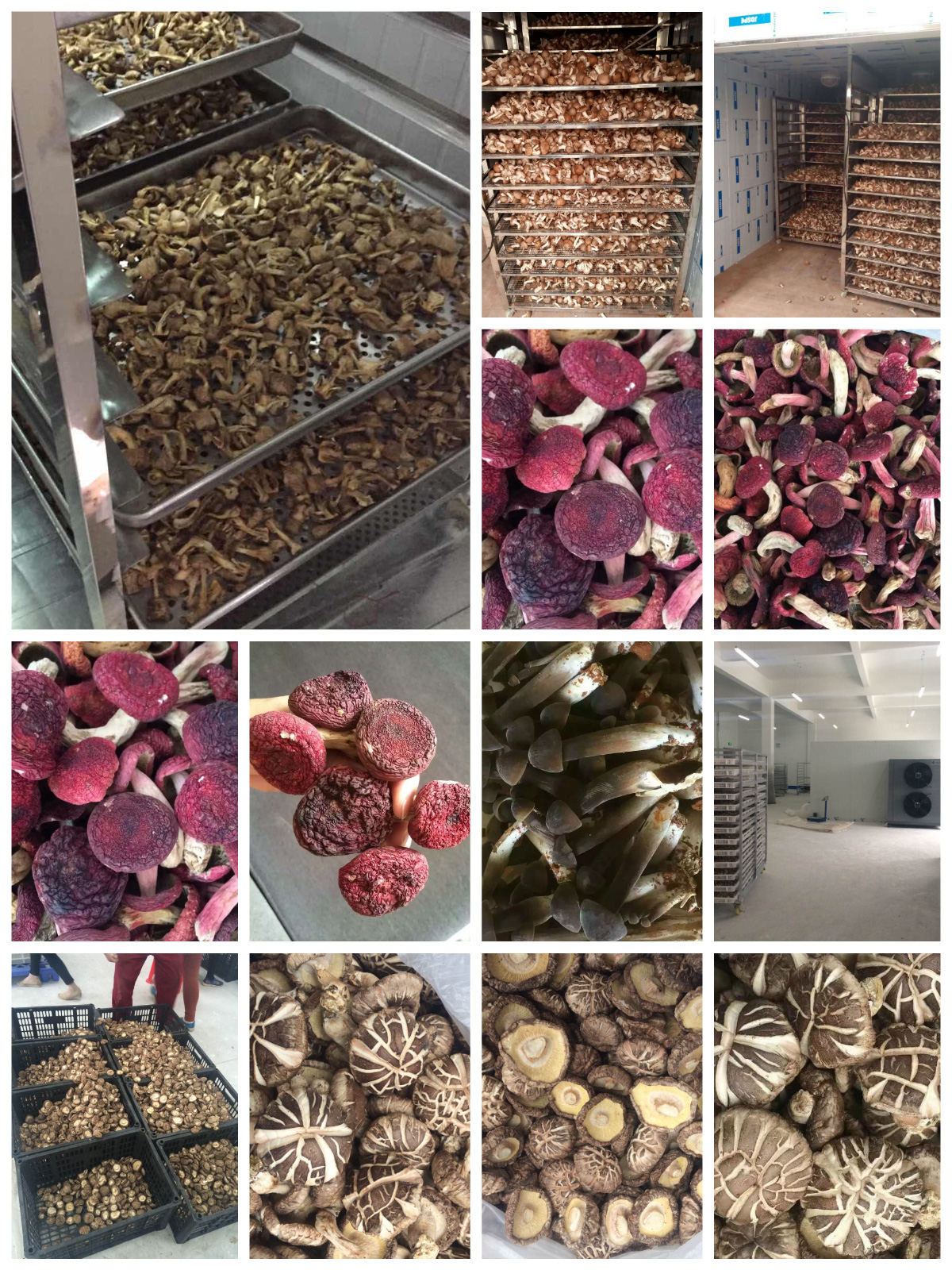

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com