Introduction: The Importance of Proper Rose Drying

Roses are prized not only for their beauty but also for their medicinal and commercial value. Drying roses effectively is critical to preserving bioactive compounds (e.g., essential oils, flavonoids) while ensuring hygiene and shelf stability. Traditional methods like sun-drying or natural air-drying often fail to eliminate insect eggs attached to petals, leading to infestation during storage. Modern heat pump drying technology, exemplified by MeiYa Air Energy Heat Pump Dryers, overcomes these challenges by combining precision temperature control, energy efficiency, and automation—delivering consistent, high-quality dried roses for global markets.

MeiYa Heat Pump Dryer: Key Advantages

- Superior Temperature Control

MeiYa’s intelligent system maintains precise temperature gradients (±1°C accuracy), protecting heat-sensitive compounds like terpenes and polyphenols. Unlike traditional ovens or dehydrators, which risk overheating, MeiYa ensures uniform drying without compromising color, aroma, or texture. - Energy Efficiency & Sustainability

Leveraging advanced vapor compression cycles, MeiYa dryers consume 75% less energy than conventional electric/gas dryers. For every 1 kWh of electricity used, 4 kWh of heat energy is generated—reducing operational costs and carbon footprint. - Fully Automated Operation

Minimal manual intervention is required. The system auto-adjusts humidity, airflow direction, and temperature phases based on preset profiles, ensuring repeatable results. - Hygienic & Safe

Closed-loop drying eliminates contamination risks. No combustion emissions or open flames ensure compliance with food safety and fire regulations. - Versatile Scalability

Compact, modular designs suit small artisanal producers and industrial facilities alike. Units can be installed indoors or outdoors with minimal space requirements.

MeiYa Rose Drying Process: A 3-Phase Approach

Phase 1: Pre-Drying Preparation

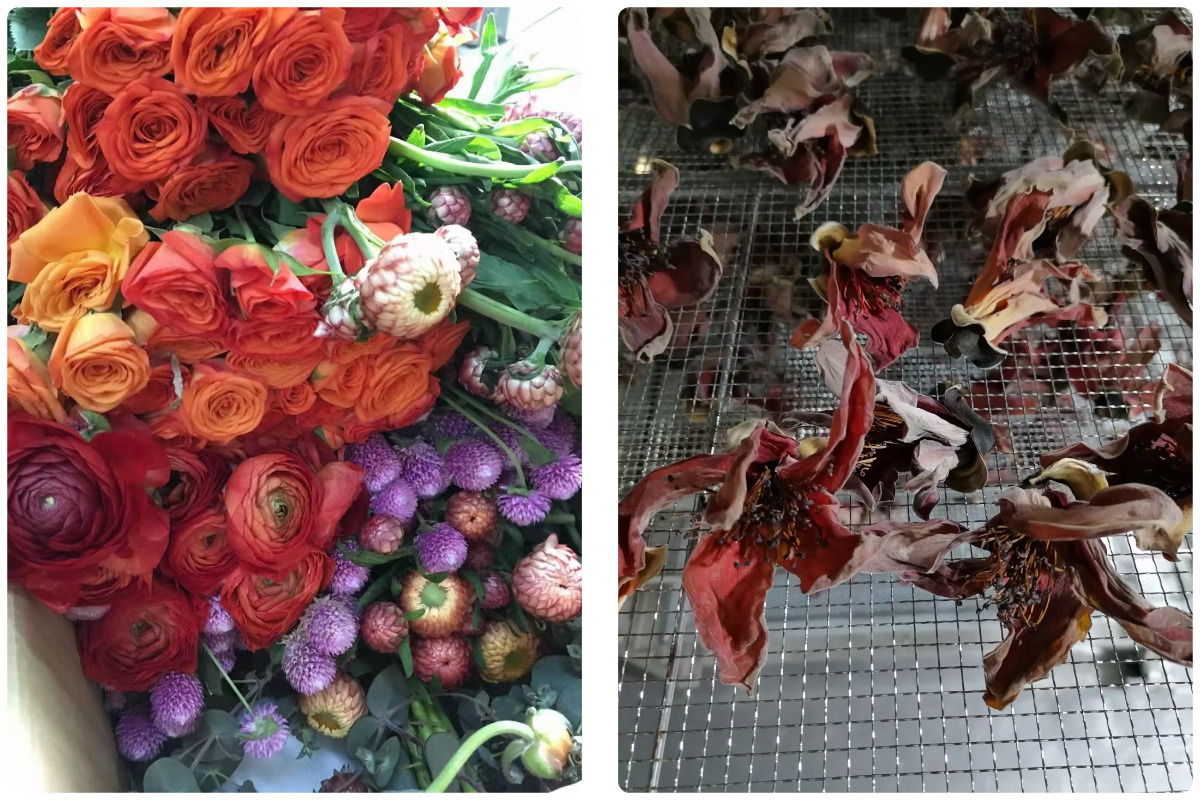

- Harvesting Standards: Select buds at the “pre-bloom” stage (calyx slightly open, tips reddish). Discard damaged or open flowers.

- Loading: Arrange buds uniformly on perforated trays, petals facing downward. Avoid overcrowding to ensure airflow.

- Pre-Treatment: Optional dehumidification at 35°C for 1–2 hours to remove surface moisture.

Phase 2: Multi-Stage Drying Cycle

Total drying time: 16–19 hours (adjustable per batch size)

- Initial Drying: 35–40°C for 3 hours (gentle moisture removal).

- Intermediate Phase: Gradually increase to 45–50°C over 5 hours to accelerate drying without thermal shock.

- Final Phase: Maintain 50–55°C for 8–10 hours. Continuous airflow (supply fan) prevents moisture pockets.

Phase 3: Post-Drying Quality Control

- Testing: Check for moisture content (<8%). Petals should crumble easily; stems should snap, not bend.

- Packaging: Cool to ambient temperature, then vacuum-seal in food-grade bags. Store in ventilated, pest-proof containers.

Traditional vs. MeiYa Heat Pump Drying

| Factor | Traditional Methods | MeiYa Heat Pump Dryer |

|---|---|---|

| Temperature Control | Unstable; weather-dependent | Precise, programmable gradients |

| Energy Use | High (gas/electric) or inconsistent | 75% savings; 1 kWh → 4 kWh output |

| Hygiene | Risk of pests, dust, mold | Closed system; pathogen/egg elimination |

| Labor | Manual monitoring required | Fully automated; remote monitoring |

| Product Quality | Variable color, aroma loss | Vibrant color, retained bioactive compounds |

Conclusion

MeiYa Air Energy Heat Pump Dryers redefine rose drying by merging advanced technology with sustainable practices. From small-scale herbalists to commercial producers, our systems guarantee premium-quality dried roses—rich in fragrance, color, and medicinal value—while slashing operational costs. Elevate your production standards with MeiYa’s reliable, eco-friendly solution.

Contact Us Today!

📧 Email: [email protected]

📞 Contact: Ray Ren

📱 WhatsApp/WeChat/Mobile: +86 133 4676 7871

MeiYa – Empowering Quality, Preserving Nature.

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com