Introduction: The Importance of Proper Morinda Citrifolia Drying

Morinda Citrifolia (commonly known as 巴戟天), a perennial herb native to Guangdong and Guangxi provinces, is prized for its medicinal roots. Its thin, papery leaves and dense root structure make it highly sensitive to improper drying. Traditional sun-drying or conventional oven methods often lead to uneven moisture removal, over-drying, or loss of bioactive compounds, resulting in a brittle, low-value product. To preserve its quality and market value, precise temperature control, humidity management, and staged drying are critical—requirements that modern heat pump technology excels at addressing.

Why Choose MeiYa Air Source Heat Pump Dryer?

MeiYa’s advanced heat pump technology revolutionizes Morinda Citrifolia drying by combining energy efficiency, automation, and precision. Key advantages include:

- Precision Temperature Control: Maintain ±1°C accuracy to prevent overheating or under-drying.

- Energy Savings: 60–70% lower energy consumption compared to traditional electric or coal-fired dryers.

- Humidity Management: Automated dehumidification ensures optimal moisture removal at every stage.

- Reduced Labor: Fully programmable cycles minimize manual intervention.

- Eco-Friendly: Zero emissions and compliance with sustainable production standards.

Step-by-Step Drying Process for Morinda Citrifolia

Stage 1: Initial Drying (60–65°C, 8–10 Hours)

Load fresh roots into MeiYa’s drying trays, ensuring even spacing. Set the temperature to 60–65°C to remove surface moisture and reduce the root’s weight by ~40%. This stage prepares the roots for efficient core processing.

Stage 2: Resting & Decoring (6–8 Hours)

Turn off the dryer and allow roots to rest for 6–8 hours. This step softens the woody core (木心) for easy removal, a critical process to enhance the final product’s purity and medicinal efficacy.

Stage 3: Final Drying (45–65°C, 20% RH, 10 Hours)

Reload decored roots into the dryer. Gradually increase the temperature from 45°C to 65°C while maintaining 20% relative humidity. This gentle gradient preserves bioactive compounds and achieves a uniform moisture content of ≤12%.

Traditional vs. MeiYa Heat Pump Drying

| Factor | Traditional Methods | MeiYa Heat Pump |

|---|---|---|

| Temperature Control | Unstable, weather-dependent | Precise (±1°C), fully automated |

| Energy Efficiency | High fuel/energy consumption | 60–70% energy savings |

| Labor | Intensive manual monitoring | Minimal intervention required |

| Product Quality | Risk of over-drying or spoilage | Uniform drying, premium quality |

Conclusion

MeiYa’s heat pump dryer offers a scientifically optimized solution for Morinda Citrifolia processing, ensuring superior product quality, cost efficiency, and sustainability. By adopting staged temperature protocols and intelligent humidity management, producers can achieve consistent, high-value outputs while reducing operational costs.

Contact MeiYa for Your Custom Drying Solution:

📧 Email: [email protected]

📞 Contact: Ray Ren

📱 WhatsApp/WeChat/Mobile: +86 133 4676 7871

Explore MeiYa’s range of industrial drying systems tailored for herbal, agricultural, and pharmaceutical applications.

© MeiYa Sustainable Drying Technologies – Precision Engineered for Quality Preservation.

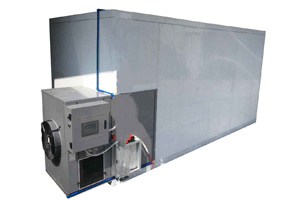

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com