Introduction to Lobelia (Roselle) Drying

Lobelia, commonly known as Roselle or Hibiscus sabdariffa, is a tropical plant prized for its vibrant calyxes and medicinal properties. Widely cultivated in regions like Yunnan and Guangdong, China, its dried flowers are used in teas, supplements, and cosmetics. However, improper drying methods can degrade its color, aroma, and nutritional value. Traditional sun-drying or coal-fired drying often leads to uneven results, contamination, or energy waste. This is where MeiYa Air Source Heat Pump Dryers excel, offering a modern, eco-friendly, and precision-controlled solution for preserving Lobelia’s quality.

Why Choose MeiYa Heat Pump Dryers?

MeiYa’s advanced heat pump technology revolutionizes Lobelia drying with these advantages:

- Energy Efficiency: Consumes 60–70% less energy than conventional dryers.

- Precision Temperature & Humidity Control: Ensures uniform drying and optimal retention of pigments and nutrients.

- Zero Pollution: Fully enclosed drying process eliminates dust or external contaminants.

- Automation: Reduces labor costs and human error with programmable settings.

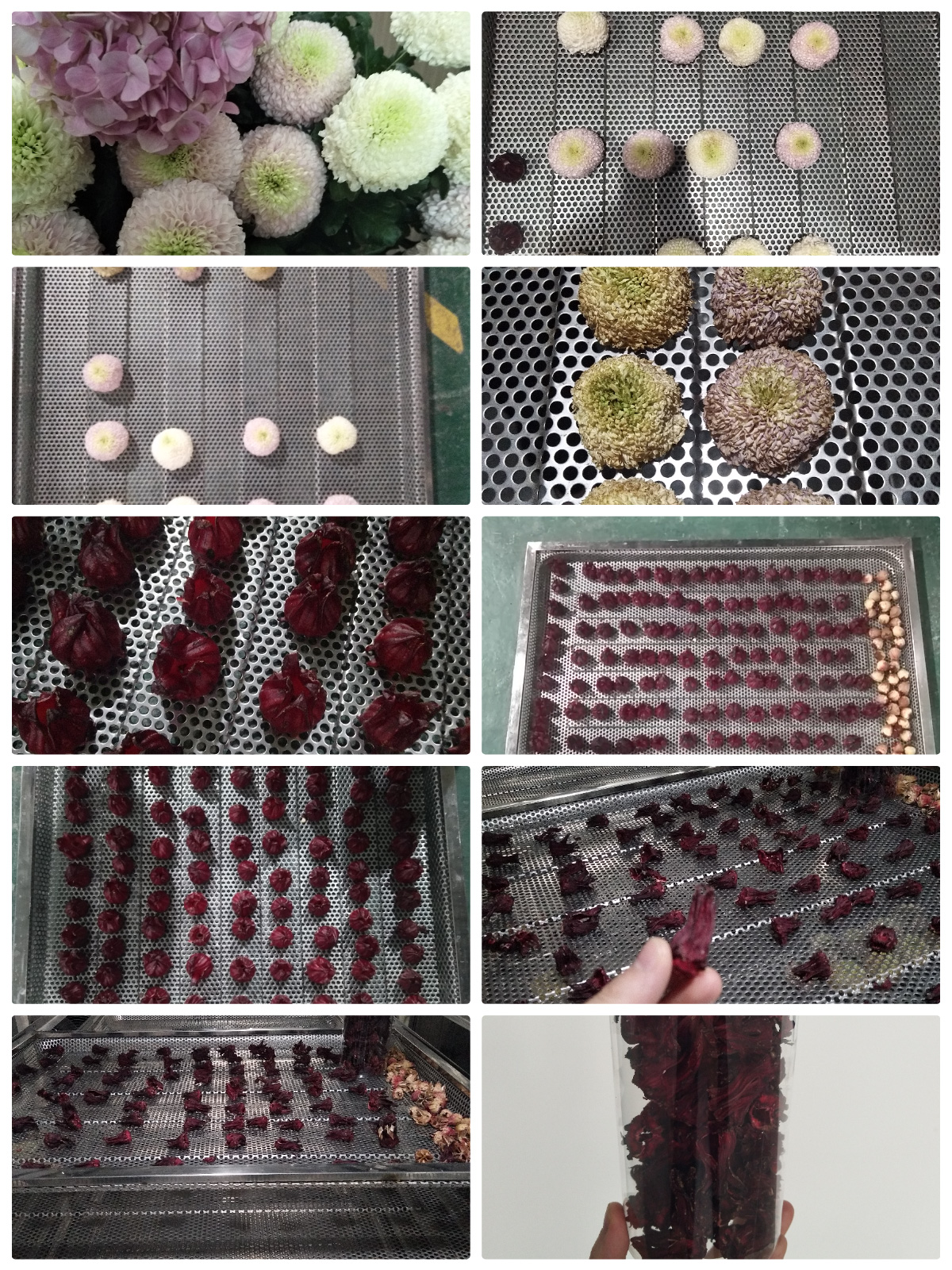

Step-by-Step Lobelia Drying Process with MeiYa

1. Pre-Drying Treatment: Color Preservation

Lobelia’s signature red hue is sensitive to oxidation. MeiYa recommends:

- Enzyme Deactivation: Use steam blanching (95–100°C for 2–3 minutes) or microwave treatments to stabilize pigments and halt enzymatic browning.

- Uniform Sorting: Remove damaged flowers to ensure consistent drying.

2. Tray Loading Best Practices

- Material: Use MeiYa’s 304 stainless steel mesh trays to prevent contamination.

- Spacing: Arrange flowers in 8–12 cm layers across trays to promote airflow.

- Capacity: A standard 25 m³ MeiYa drying chamber holds ~800 kg of fresh flowers (8 trolleys × 12–14 trays each).

3. Smart Drying Stages

MeiYa’s programmable system automates the following phases:

- Phase 1 (Initial Drying):

- Temperature: 35°C → 38°C → 42°C (2 hours per stage).

- Humidity: 50% → 30%.

- Purpose: Gentle moisture removal to fix color and shape.

- Phase 2 (Intermediate Drying):

- Temperature: 46°C → 50°C (2 hours per stage).

- Humidity: 30% → 15%.

- Purpose: Accelerate drying without thermal shock.

- Phase 3 (Final Drying):

- Temperature: 55–60°C (11 hours) → 65°C (1 hour).

- Humidity: 15% → 8%.

- Purpose: Enhance aroma and ensure complete dehydration.

Total Time: 22–23 hours (vs. 3–5 days for traditional methods).

Traditional vs. MeiYa Heat Pump Drying

| Factor | Traditional Methods | MeiYa Heat Pump Dryer |

|---|---|---|

| Energy Use | High (coal, electricity) | Ultra-low (ambient heat recovery) |

| Temperature Control | Unstable, manual adjustments | Precise ±1°C accuracy |

| Color Retention | Risk of fading or browning | Vibrant, consistent results |

| Labor | Intensive monitoring required | Fully automated process |

Conclusion

MeiYa Air Source Heat Pump Dryers redefine Lobelia processing by combining efficiency, quality, and sustainability. Whether for small farms or industrial facilities, our technology ensures premium dried products that meet global standards. Say goodbye to inconsistent results and hello to profitability with MeiYa.

Contact Us Today!

- Email: [email protected]

- Contact Person: Ray Ren

- Mobile/WhatsApp/WeChat: +86 133 4676 7871

Upgrade your Lobelia drying with MeiYa – where innovation meets nature’s finest.

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com