Introduction: The Importance of Precision Drying for Saffron

Saffron (Crocus sativus), renowned for its vibrant color, distinct aroma, and medicinal properties, requires meticulous post-harvest processing to preserve its quality. Fresh saffron flowers contain over 85% moisture, making them highly perishable and unsuitable for long-term storage or transportation. Traditional drying methods—such as sun drying—are weather-dependent, labor-intensive, and risk contamination or uneven drying. To address these challenges, MeiYa Air Source Heat Pump Dryers offer a modern, efficient, and sustainable solution for producing premium-grade dried saffron.

Why Choose MeiYa Heat Pump Dryers?

MeiYa’s advanced heat pump technology revolutionizes saffron drying by combining precision, energy efficiency, and automation. Key advantages include:

- Intelligent Control: Automated temperature and humidity management ensure optimal drying conditions without manual intervention.

- Energy Savings: Up to 70% lower energy consumption compared to conventional methods, reducing costs to as low as $0.07 per kilogram of dried saffron.

- Uniform Quality: Multi-directional airflow design prevents over-drying or scorching, preserving saffron’s natural color, flavor, and bioactive compounds.

- Eco-Friendly: Zero emissions and closed-loop heat recycling align with global sustainability standards.

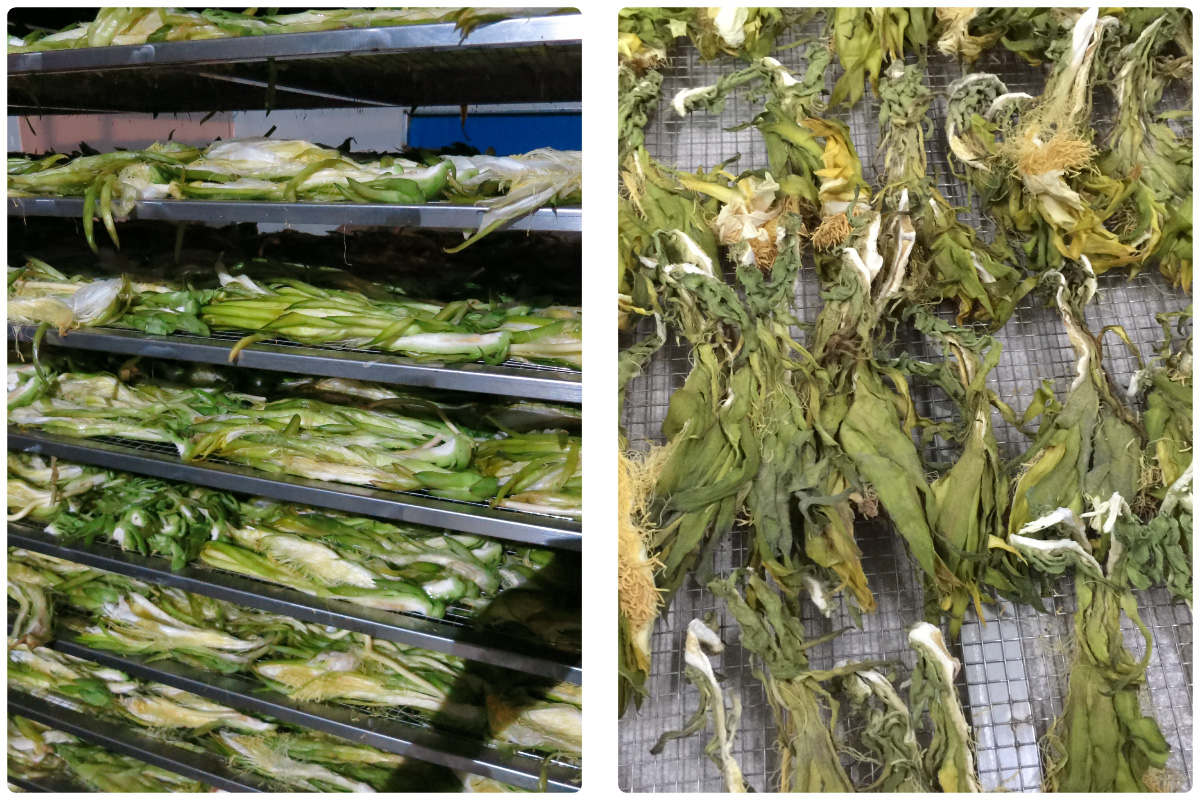

MeiYa’s 3-Stage Saffron Drying Process

Based on extensive R&D and industry expertise, MeiYa recommends the following protocol for processing 4 metric tons of saffron flowers in a 120 m³ drying chamber:

Stage 1: Softening Phase (5 Hours)

- Temperature: 55°C

- Humidity: 60%

- Objective: Gradually reduce moisture content while preventing cellular rupture. This stage prepares the flowers for efficient dehydration.

Stage 2: Active Dehydration (10 Hours)

- Temperature: 60°C

- Humidity: 30%

- Mode: Continuous drying + active dehumidification

- Objective: Rapid moisture removal without compromising structural integrity. The system intelligently adjusts airflow to maintain consistency.

Stage 3: Final Conditioning (5 Hours)

- Temperature: 65°C

- Humidity: 12%

- Mode: Intermittent dehumidification

- Objective: Achieve the ideal moisture content (<10%) and enhance shelf stability. Operators monitor color and texture to ensure compliance with premium standards.

Key Success Factors:

- Prioritize humidity control in early stages to lock in vibrant coloration.

- Avoid overheating to preserve delicate aromatic compounds.

Traditional vs. MeiYa Heat Pump Drying

| Criteria | Traditional Sun Drying | MeiYa Heat Pump Dryer |

|---|---|---|

| Weather Dependency | High (requires sunny, dry days) | None (operates in all conditions) |

| Labor Costs | Intensive manual oversight | Fully automated |

| Consistency | Risk of mold or uneven drying | Uniform results guaranteed |

| Energy Efficiency | Low (prolonged drying times) | High (optimized heat recovery) |

Conclusion

MeiYa Air Source Heat Pump Dryers redefine saffron processing by delivering unmatched efficiency, quality, and cost-effectiveness. Our technology ensures that every batch meets stringent international standards for culinary and medicinal use, empowering producers to scale operations while minimizing environmental impact.

For custom drying solutions or technical support, contact MeiYa’s expert team:

📧 Email: [email protected]

📞 Contact: Ray Ren

📱 WhatsApp/WeChat/Mobile: +86 133 4676 7871

Preserve Nature’s Bounty with MeiYa—Where Innovation Meets Tradition.

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com