Introduction: The Importance of Sea Fish Drying

Sea fish drying is a time-honored preservation method that extends shelf life while retaining essential nutrients. However, traditional drying methods—such as open-air sun drying or coal-fired heating—face challenges like weather dependency, bacterial contamination, uneven drying, and high energy consumption. These limitations hinder product quality and scalability. MeiYa Air Source Heat Pump Dryer offers a modern, sustainable solution, ensuring consistent quality, food safety, and energy efficiency for sea fish processing.

MeiYa Heat Pump Dryer: Key Advantages

- Energy Efficiency & Sustainability

MeiYa’s technology extracts ambient heat from the air, consuming minimal electricity to generate significant thermal energy. Integrated with a secondary waste heat recovery system, it reduces energy use by over 60% compared to conventional dryers. - Precision Control & Automation

The intelligent control panel automates temperature, humidity, and airflow adjustments, mimicking optimal natural drying conditions without manual intervention. - Hygienic & Pollution-Free

Operating at ambient pressure and temperature, MeiYa dryers eliminate pollutants, smoke, or harmful emissions, ensuring compliance with food safety standards. - Year-Round Reliability

Unaffected by weather or seasonal changes, MeiYa guarantees uninterrupted production and superior product consistency.

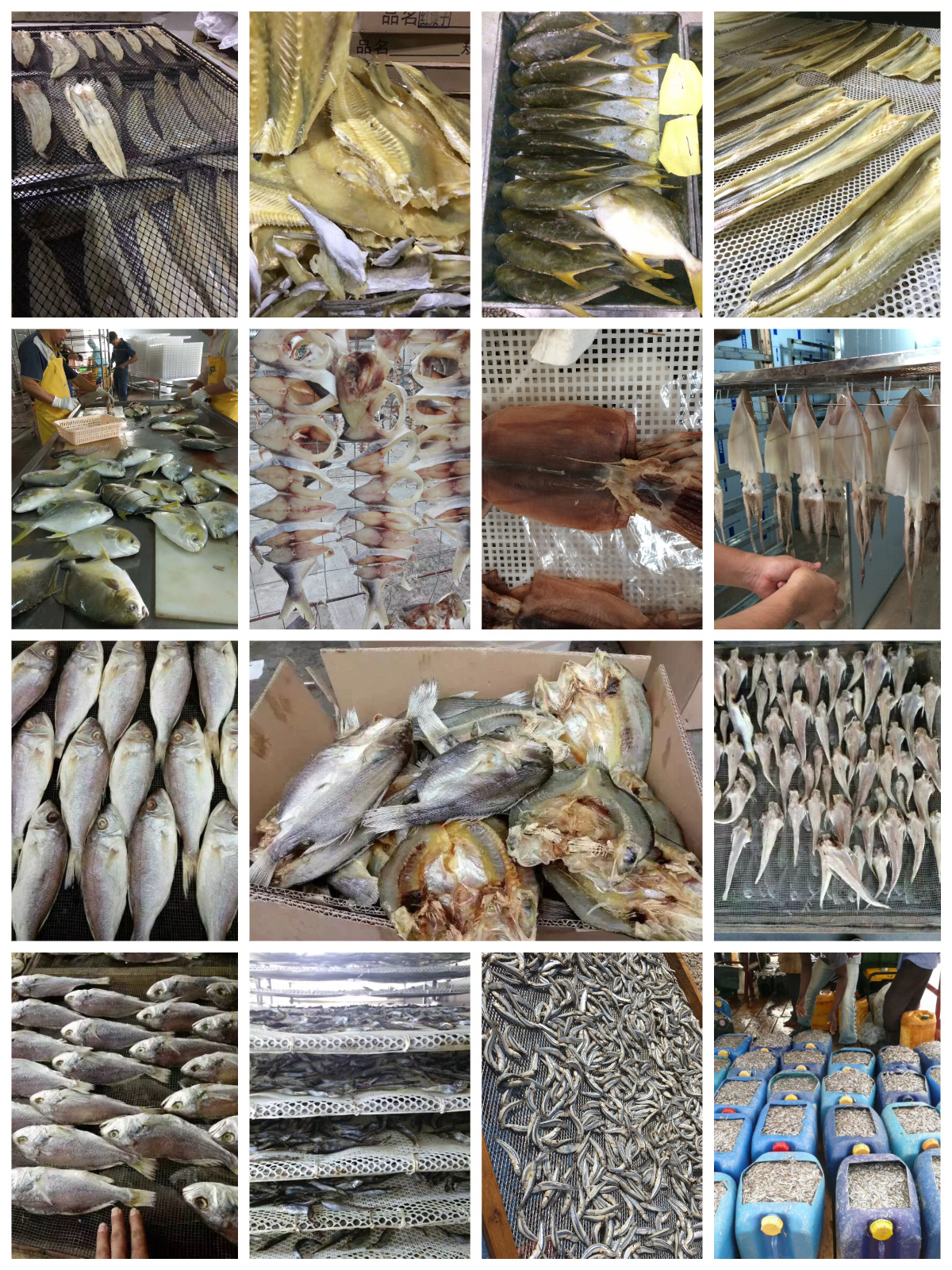

Sea Fish Drying Process with MeiYa

1. Preparation: Filleting & Washing

- Filleting: Fish are split into halves or thirds depending on size (back-fillet for large fish, belly-fillet for smaller ones). Organs and membranes are carefully removed.

- Washing: Freshly filleted fish are rinsed to remove blood, mucus, and debris, then drained to prepare for salting.

2. Salting

Salt (18–24% of fish weight) is evenly rubbed onto the flesh, gills, and cavities. Fish are layered in brine tanks, weighted down to immerse fully in saltwater for 4–5 hours. This step enhances preservation and flavor.

3. Drying with MeiYa Heat Pump Dryer

- Loading: Salted fish are arranged on trays and loaded into the MeiYa drying chamber.

- Drying Cycle:

- Phase 1 (Dehydration): Low-temperature drying (30–35°C) removes surface moisture while preventing case-hardening.

- Phase 2 (Uniform Drying): Temperature gradually increases (40–45°C) to evenly reduce internal moisture.

- Phase 3 (Final Conditioning): Gentle airflow ensures optimal texture and prevents over-drying.

- Duration: Total drying time ranges between 22–28 hours, adjustable via the automated system.

4. Packaging & Storage

Dried fish are vacuum-sealed or stored in airtight containers. For extended shelf life, refrigeration (below 10°C) is recommended.

Traditional vs. MeiYa Heat Pump Drying

| Factor | Traditional Methods | MeiYa Heat Pump Dryer |

|---|---|---|

| Energy Use | High (coal/fuel) or weather-dependent | 60%+ energy savings, renewable heat sources |

| Hygiene | Risk of insects, dust, bacteria | Closed-loop system, no contamination |

| Labor | Intensive manual monitoring | Fully automated, 24/7 operation |

| Product Quality | Uneven drying, nutrient loss, discoloration | Consistent texture, retained nutrients, golden hue |

Conclusion: Elevate Your Production with MeiYa

MeiYa Air Source Heat Pump Dryer redefines sea fish processing by combining cutting-edge technology with eco-friendly practices. Its precision, efficiency, and automation make it ideal for businesses aiming to scale production while ensuring premium quality and compliance.

Contact Us Today!

- Email: [email protected]

- Contact: Ray Ren

- WhatsApp/WeChat/Mobile: +86 133 4676 7871

Transform your sea fish drying process with MeiYa—where innovation meets tradition.

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com