Introduction: The Importance of Precision Drying for Sea Cucumbers

Sea cucumbers, a nutrient-rich marine delicacy and medicinal resource, require meticulous processing to preserve their quality, texture, and bioactive compounds. Traditional drying methods, such as sun-drying or coal-fired dehydration, often lead to inconsistent results due to weather dependency, over-drying, or contamination risks. In contrast, modern heat pump drying technology offers a controlled, energy-efficient solution. MeiYa Air Source Heat Pump Dryers are engineered to deliver precise temperature and humidity management, ensuring superior product quality while reducing operational costs.

Why Choose MeiYa Heat Pump Dryers?

- Energy Efficiency

MeiYa dryers utilize advanced heat recovery technology, consuming up to 60% less energy than conventional methods. This aligns with global sustainability goals while lowering production costs. - Precision Control

Our intelligent control system allows operators to program temperature, humidity, and drying stages with accuracy (±1°C/±5% RH). This eliminates guesswork and ensures uniformity across batches. - Cold-Drying Mode for Premium Products

For high-value products like salt-free dried sea cucumbers, MeiYa’s cold-drying mode (10–30°C) preserves natural color, texture, and aroma, meeting premium market standards. - Reduced Labor & Contamination Risks

Automated operation minimizes manual intervention, reducing human error and contamination risks during prolonged drying cycles.

Step-by-Step Drying Process Using MeiYa Dryers

1. Pre-Treatment

- Cleaning & Gutting: Rinse fresh sea cucumbers thoroughly (5–6 cycles) and remove internal organs via a 2–3 cm ventral incision.

- Blanching: Blanch cleaned sea cucumbers in 90°C water for 30 minutes until they shrink and develop distinct spines.

2. Drying Stages

- Stage 1 (Initial Dehydration):

Set temperature to 35–40°C with 40–50% RH for 8–10 hours to remove surface moisture. - Stage 2 (Core Drying):

Gradually increase temperature to 45–50°C (30–35% RH) for 12–15 hours to eliminate internal moisture. - Stage 3 (Final Polishing):

For premium-grade products, activate cold-drying mode (10–30°C, 15–20% RH) for 6–8 hours to lock in natural gloss and nutrients.

3. Quality Check

Finished products should have a moisture content below 15%, uniform texture, and no discoloration.

Traditional vs. MeiYa Heat Pump Drying

| Factor | Traditional Methods | MeiYa Heat Pump Dryer |

|---|---|---|

| Temperature Control | Unstable, weather-dependent | Programmable (±1°C precision) |

| Energy Use | High (coal/electricity) | 60% energy savings |

| Labor | Intensive monitoring required | Fully automated operation |

| Product Quality | Risk of over-drying/contamination | Consistent, premium-grade output |

Conclusion: Elevate Your Sea Cucumber Processing with MeiYa

MeiYa Air Source Heat Pump Dryers redefine efficiency and quality in sea cucumber processing. By integrating smart technology with eco-friendly design, we empower producers to meet stringent industry standards while maximizing profitability. Whether producing salt-dried or premium salt-free varieties, MeiYa ensures optimal results every time.

Contact Us Today!

Email: [email protected]

Contact: Ray Ren

WhatsApp/WeChat/Mobile: +86 133 4676 7871

MeiYa – Innovating Drying Solutions for a Sustainable Future.

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

Our Projects:

Our Factory:

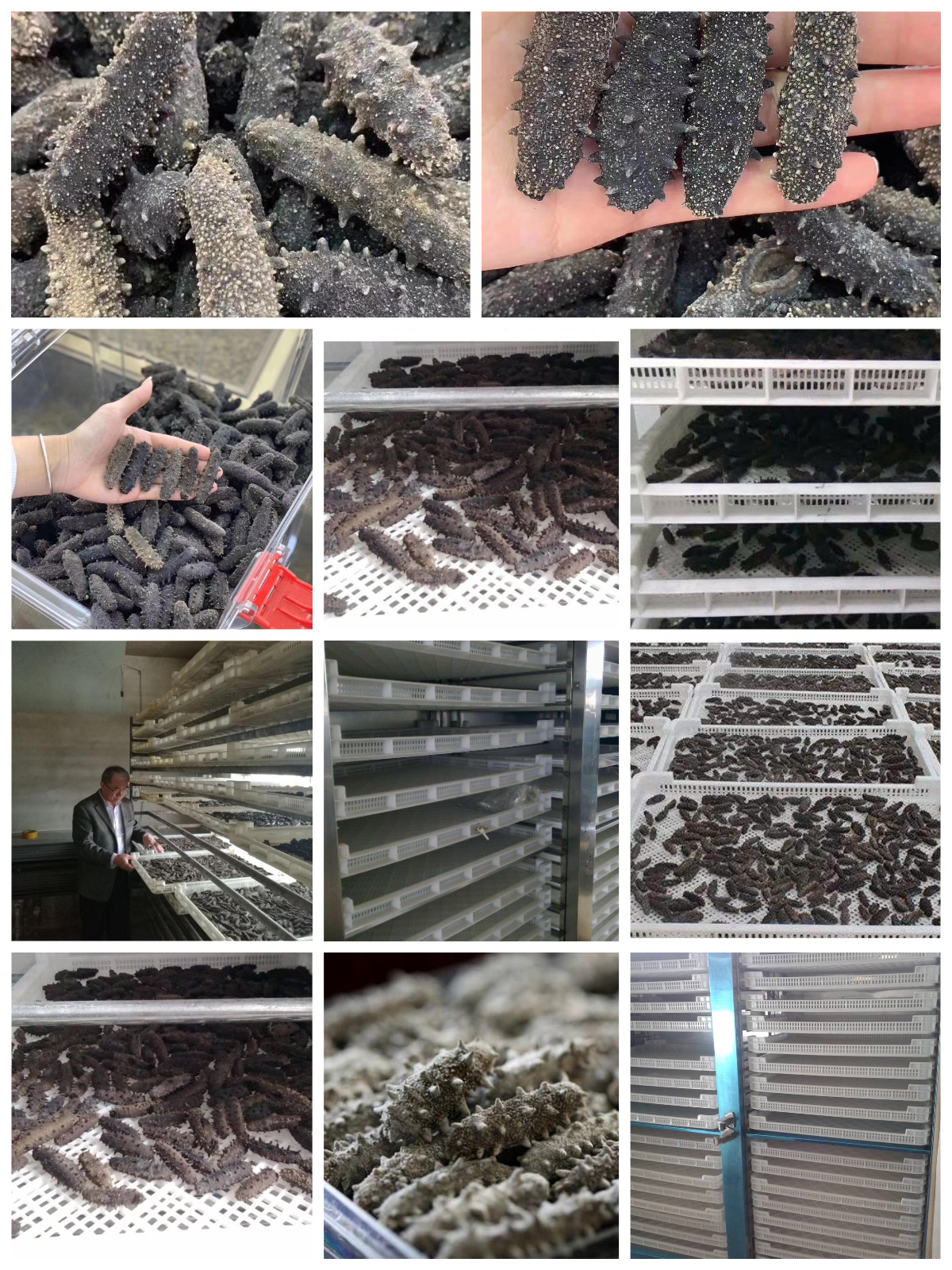

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com