Introduction: The Importance of Controlled Beef Drying

Beef jerky, a popular and nutritious snack, requires precise drying to preserve flavor, texture, and shelf life. Traditional drying methods often lead to inconsistent results due to fluctuating temperatures and humidity. At MeiYa, we leverage advanced air source heat pump technology to deliver energy-efficient, automated, and precisely controlled drying solutions. This article outlines our optimized beef drying process, designed to ensure superior product quality while reducing operational costs.

Why Choose MeiYa Heat Pump Dryers?

MeiYa’s air source heat pump dryers offer distinct advantages over conventional methods (e.g., sun-drying or coal-fired systems):

- Energy Efficiency: Consumes 60% less energy than traditional dryers by recycling thermal energy.

- Precision Control: Maintains stable temperature and humidity levels for uniform drying.

- Zero Emissions: Eco-friendly operation with no combustion or pollutants.

- Automation: Minimal manual intervention required, ensuring consistent batch quality.

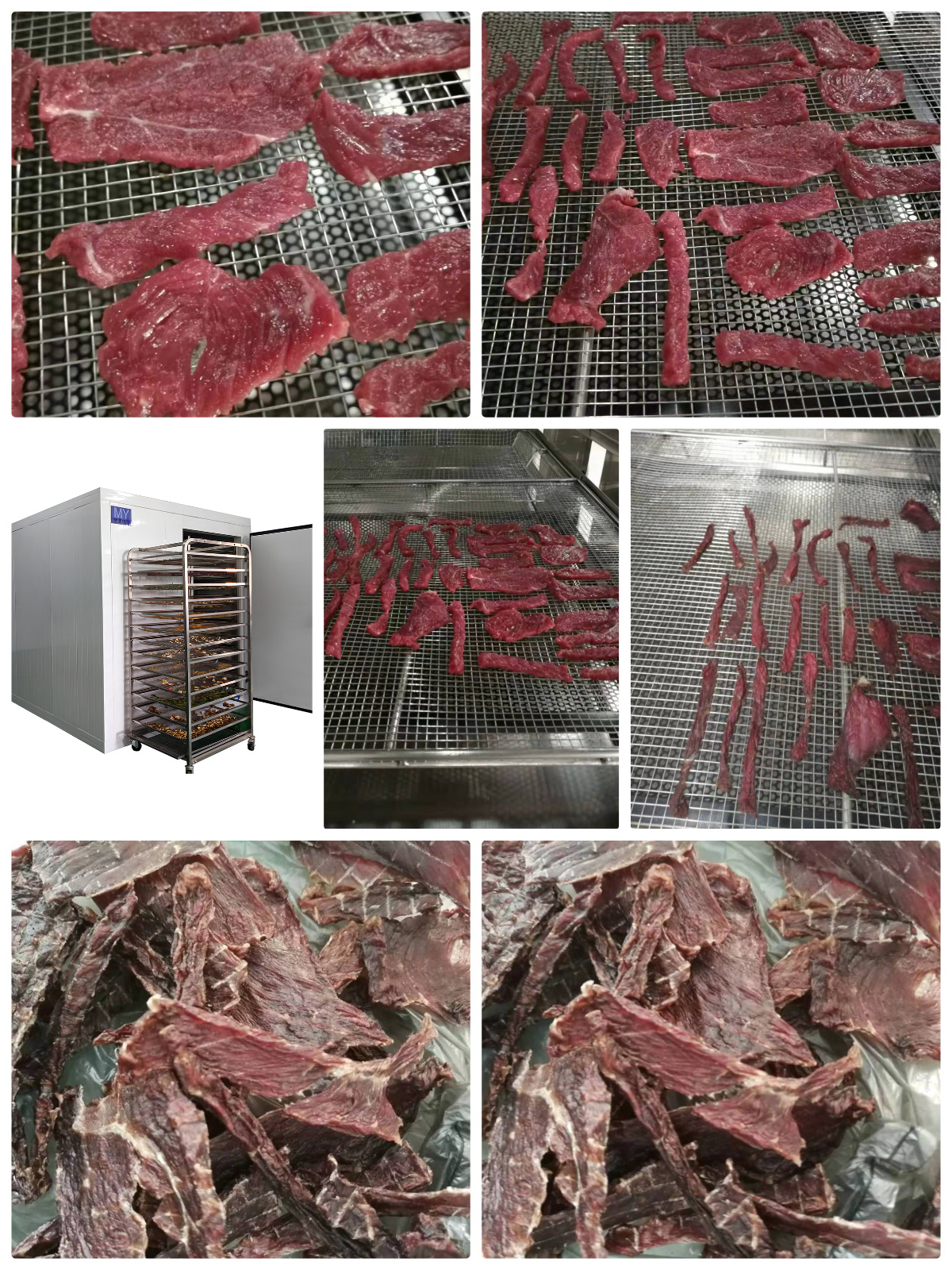

MeiYa’s 3-Stage Beef Drying Process

Stage 1: Pre-Drying & Fermentation

- Temperature: Rapidly increase to 60–65°C within 2 hours of loading.

- Humidity: No dehumidification during this phase.

- Duration: 5–6 hours.

- Purpose: Activates fermentation to enhance flavor and inhibit bacterial growth.

Preparation Tips:

- Hang beef strips vertically with adequate spacing (no dripping, no overlapping).

- Ensure proper airflow to prevent uneven drying.

Stage 2: Low-Temperature Slow Drying (Color Fixation & Shaping)

- Temperature: Adjust to 52–54°C.

- Humidity: Maintain at 45–50%.

- Duration: 3–4 hours.

- Key Observations:

- Beef transitions from pale to vibrant red.

- Gradual contraction begins; monitor surface texture.

- Optional Technique: Alternate mild heating and cooling cycles to prevent hardening.

Stage 3: High-Temperature Rapid Drying (Final Moisture Removal)

- Temperature: Elevate to 60–65°C.

- Humidity: Reduce to ~35%.

- Duration: 10–12 hours.

- Target Moisture: ≤15% (ideal for long-term storage).

- Final Quality Check:

- Color: Uniform dark red.

- Texture: Firm to the touch with slight flexibility.

Total Drying Time: ~36 hours (varies with strip thickness and load density).

Traditional vs. MeiYa Heat Pump Drying: Key Differences

| Factor | Traditional Methods | MeiYa Heat Pump Dryer |

|---|---|---|

| Temperature Control | Unstable, weather-dependent | Precise (±1°C), fully automated |

| Energy Use | High (coal/electricity) | Ultra-low (heat recovery system) |

| Labor | Intensive monitoring required | Minimal intervention |

| Consistency | Variable quality | Uniform batches |

Conclusion

MeiYa’s air source heat pump dryers revolutionize beef jerky production by combining cutting-edge technology with operational simplicity. Our three-stage drying protocol ensures optimal color retention, flavor development, and shelf stability—critical for commercial producers seeking scalability and sustainability.

Upgrade to MeiYa for:

✅ Higher profit margins (reduced energy costs).

✅ Premium product quality.

✅ Compliance with global food safety standards.

Contact Us for a Customized Drying Solution!

- Email: [email protected]

- Sales Manager: Ray Ren

- Mobile/WhatsApp/WeChat: +86 133 4676 7871

MeiYa Drying Solutions – Empowering Quality, Preserving Nature.

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com