The Importance of Efficient Pineapple Drying

Pineapple, a tropical fruit rich in vitamins and enzymes, requires careful post-harvest processing to preserve its flavor, texture, and nutritional value. Traditional drying methods, such as sun drying or conventional hot-air systems, often lead to uneven dehydration, nutrient loss, and contamination risks. In contrast, modern heat pump drying technology—exemplified by MeiYa Heat Pump Dryers—offers precise temperature control, energy efficiency, and consistent results, making it ideal for commercial-scale pineapple processing.

Why Choose MeiYa Heat Pump Dryer?

MeiYa’s advanced heat pump drying technology revolutionizes pineapple processing with the following advantages:

- Energy Efficiency: By absorbing ambient heat from the air, MeiYa dryers consume up to 70% less energy than traditional electric or fuel-based systems.

- Precision Control: Automated adjustments to temperature and humidity ensure uniform drying while preserving natural color and flavor.

- Eco-Friendly Operation: Zero emissions, no combustion, and reduced carbon footprint align with sustainable production goals.

- Low Labor Dependency: Fully automated cycles minimize manual intervention, reducing operational costs.

- Versatility: Suitable for sliced, diced, or whole pineapples, accommodating diverse product requirements.

Step-by-Step Pineapple Drying Process with MeiYa Heat Pump Dryer

1. Preparation

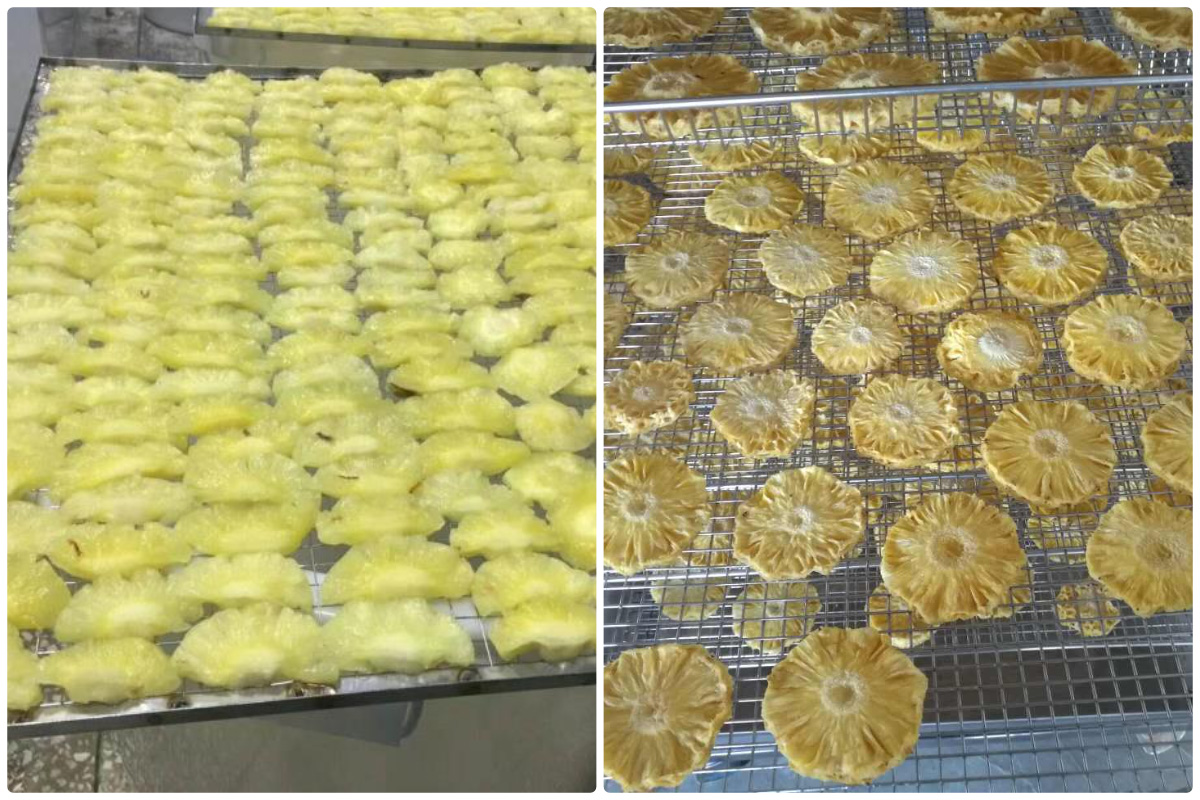

• Slicing: Cut fresh pineapples into uniform 5–8 mm slices to ensure even drying. Remove the core and rind for optimal texture.

• Pretreatment (Optional): Lightly blanch slices in a citric acid solution (1–2%) to prevent browning and enhance shelf life.

2. Loading the Dryer

Arrange pineapple slices in a single layer on mesh trays, allowing adequate airflow. Avoid overcrowding to maintain consistency.

3. Drying Stages

MeiYa’s intelligent drying system operates in five phases to maximize quality:

• Phase 1: Initial Dehydration

• Temperature: 50°C

• Duration: 1.5 hours

• Objective: Gentle warming to equalize internal and external moisture levels.

• Phase 2: Active Moisture Removal

• Temperature: 53°C

• Humidity Control: Continuous dehumidification to reduce humidity to 40%.

• Key Action: Rapid moisture extraction without overheating.

• Phase 3: Intensive Drying

• Temperature: 60°C

• Humidity Control: Further reduce humidity to 26%.

• Focus: Accelerate evaporation while maintaining nutrient integrity.

• Phase 4: Stabilization

• Temperature: 56°C

• Humidity Control: Lower humidity to 20%.

• Purpose: Balance residual moisture for crisp texture.

• Phase 5: Final Conditioning

• Temperature: 50°C

• Humidity Control: Maintain 18% humidity for 1 hour.

• Outcome: Achieve a moisture content of 10–12%, ideal for packaging and storage.

4. Post-Drying Handling

Cool dried slices to room temperature before packaging in airtight containers or vacuum-sealed bags.

Traditional vs. MeiYa Heat Pump Drying: Key Differences

| Factor | Traditional Methods | MeiYa Heat Pump Dryer |

|---|---|---|

| Energy Use | High (fuel/electricity) | Low (ambient heat absorption) |

| Temperature Control | Manual, inconsistent | Automated, precise adjustments |

| Drying Time | 24–48 hours (sun drying) | 8–12 hours |

| Product Quality | Risk of contamination, uneven | Uniform, hygienic, nutrient-rich |

| Labor Costs | High (frequent monitoring) | Minimal (automated cycles) |

Conclusion

MeiYa Heat Pump Dryers redefine pineapple drying by combining efficiency, precision, and sustainability. Whether producing snacks, ingredients, or value-added products, MeiYa ensures superior quality while reducing operational costs. Elevate your pineapple processing with technology designed for excellence.

Contact Us Today! • Email: [email protected]

• Contact Person: Ray Ren

• WhatsApp/WeChat/Mobile: +86 133 4676 7871

Discover how MeiYa can transform your drying operations—request a customized solution now!

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com