Introduction: The Importance of Lemon Drying

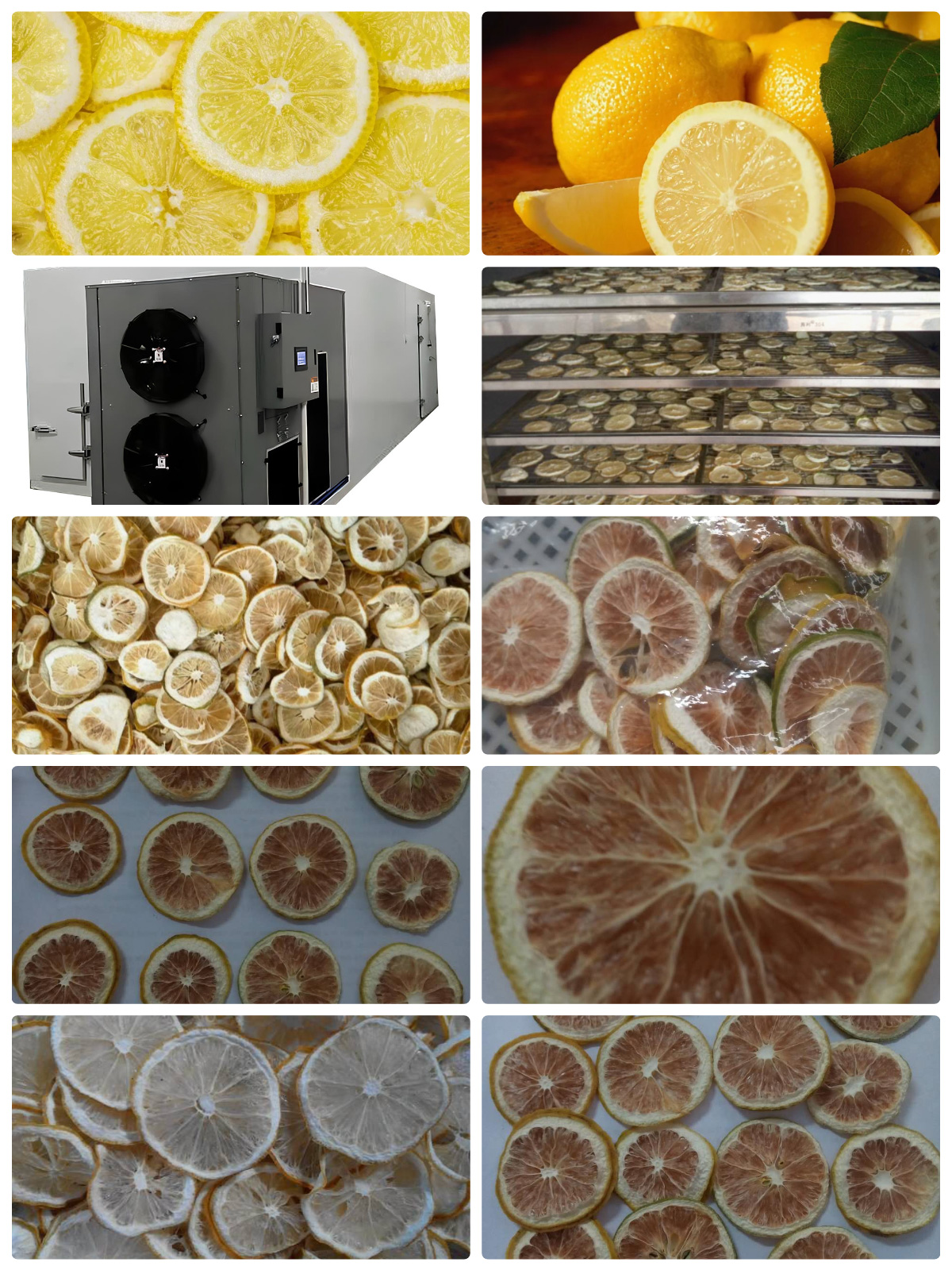

Lemon slices are a popular dried fruit product, valued for their tangy flavor and rich nutrients like vitamin C and citric acid. However, improper drying methods often lead to oxidation and caramelization, resulting in darkened, low-quality products. Traditional drying techniques (e.g., coal or wood-fired heating) suffer from poor temperature control, high energy consumption, and environmental pollution. In contrast, MeiYa Air Source Heat Pump Dryers offer a modern, sustainable solution that preserves color, flavor, and nutrients while minimizing operational costs.

Why Choose MeiYa Air Source Heat Pump Dryer?

MeiYa’s advanced heat pump technology revolutionizes lemon drying with the following advantages:

- Precise Temperature Control

Maintains low-to-moderate drying temperatures (40–60°C) to prevent sugar caramelization and oxidation, ensuring bright, golden-yellow slices. - Closed-Loop Dehumidification System

Reduces oxygen exposure by recirculating air within the drying chamber, significantly slowing oxidation. - Energy Efficiency

Recovers and reuses waste heat, consuming 70% less energy than traditional methods. - Uniform Airflow Design

Patented 360° airflow technology ensures even drying across all trays, eliminating hotspots. - Fully Automated Operation

Smart humidity and temperature sensors minimize manual intervention, guaranteeing consistent results.

Step-by-Step Lemon Drying Process with MeiYa Dryer

1. Pre-Treatment

• Cleaning: Wash fresh, ripe lemons thoroughly using saltwater, baking soda, or ultrasonic methods to remove pesticide residues and wax.

• Slicing: Cut into uniform 3–4mm slices with a mechanical slicer (±1mm tolerance). Avoid stacking slices during tray placement.

2. Loading

Arrange slices in a single layer on perforated trays to maximize airflow. A standard MeiYa dryer (e.g., 12HP model) processes 1,000–1,300 kg per batch.

3. Drying Stages

• Stage 1 – Initial Dehydration (0–6 hours):

Temperature: 40–43°C | Humidity: 30%

Removes surface moisture while preserving cell structure.

• Stage 2 – Balanced Drying (6–12 hours):

Temperature: 45°C | Humidity: 20%

Gradual moisture reduction to prevent sugar migration.

• Stage 3 – Final Curing (12–20 hours):

Temperature: 50°C | Humidity: <10%

Achieves ideal texture (5–8% moisture content) without discoloration.

Note: Total drying time varies based on slice thickness, lemon ripeness, and ambient conditions.

Traditional vs. MeiYa Heat Pump Drying

| Factor | Traditional Methods | MeiYa Heat Pump Dryer |

|---|---|---|

| Temperature Control | Unstable, often exceeding 70°C | Precise 40–60°C range |

| Oxidation Risk | High (frequent air exchange) | Low (closed-loop system) |

| Energy Efficiency | High fuel consumption | 70% energy savings |

| Environmental Impact | CO₂ emissions, pollution | Zero direct emissions |

| Labor Dependency | Manual monitoring required | Fully automated |

Conclusion

MeiYa Air Source Heat Pump Dryers redefine lemon drying by combining cutting-edge technology with eco-friendly performance. Our solution ensures vibrant color retention, nutrient preservation, and superior product quality while slashing operational costs. For commercial-scale producers seeking to enhance efficiency and profitability, MeiYa delivers unmatched reliability.

Contact Us Today! 📧 Email: [email protected]

📞 Contact: Ray Ren

📱 WhatsApp/WeChat/Mobile: +86 133 4676 7871

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com