Banana drying is a critical process in preserving the fruit’s natural flavor, color, and nutritional value. However, improper drying techniques often lead to undesirable outcomes such as browning, nutrient loss, or uneven texture. At MeiYa, we specialize in advanced air source heat pump drying technology that ensures high-quality banana slices while minimizing energy consumption and manual intervention.

Why Choose MeiYa Heat Pump Dryers?

Traditional drying methods, such as sun-drying or conventional hot-air systems, face challenges like inconsistent temperature control, high energy costs, and vulnerability to environmental factors. In contrast, MeiYa’s heat pump dryers offer:

- Precise Temperature Control: Maintains optimal drying conditions (60–65°C) to prevent sugar caramelization (common at >80°C) and under-drying.

- Energy Efficiency: Reduces energy consumption by up to 60% compared to traditional methods.

- Automated Operation: Minimizes labor costs with smart humidity and temperature sensors.

- Uniform Airflow: Ensures even drying across all batches, preserving color and texture.

Step-by-Step Banana Drying Process with MeiYa

1. Raw Material Preparation

Select bananas at the perfect ripeness—fully mature but not overripe. Discard damaged or soft fruits. Peel and slice larger bananas lengthwise (halved), while smaller ones can be dried whole.

2. Color Protection Treatment

Banana flesh contains polyphenols that cause browning during processing. To prevent oxidation:

• Immerse slices in lemon juice (or a citric acid solution) for 5–10 minutes. This step enhances vitamin retention and inhibits enzymatic browning.

3. Drying Phases with MeiYa Dryers

• Preheating Phase: Gradually increase temperature to 60°C to avoid thermal shock.

• Main Drying Phase: Stabilize at 60–65°C for 12–15 hours. MeiYa’s intelligent system adjusts airflow and humidity dynamically to prevent over-drying.

• Final Drying Phase: Reduce temperature slightly to 55°C for 3–5 hours, achieving a 16% moisture content for crisp, shelf-stable slices.

4. Quality Control

Post-drying, inspect slices for uniformity and store in airtight packaging to retain freshness.

Why MeiYa Outperforms Traditional Methods

• Consistent Results: Traditional sun-drying risks contamination and uneven drying, while conventional dryers struggle with temperature spikes. MeiYa’s technology eliminates these issues.

• Eco-Friendly: No fossil fuels required—ideal for sustainable production.

• Reduced Labor: Automated cycles eliminate the need for constant monitoring.

Conclusion

MeiYa air source heat pump dryers revolutionize banana processing by combining precision, efficiency, and ease of use. Our technology ensures golden-yellow, nutrient-rich banana slices with minimal energy waste—perfect for commercial producers prioritizing quality and sustainability.

Contact Us Today! • Email: [email protected]

• Contact Person: Ray Ren

• WhatsApp/WeChat/Mobile: +86 133 4676 7871

Let MeiYa empower your banana drying operations with cutting-edge, reliable solutions.

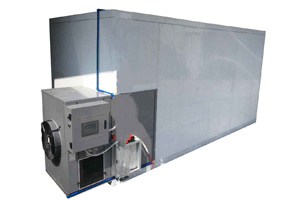

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 1650*856*1280 | 1806*1065*1280 | 2089*1260*1580 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| Model | Description | Drying Capacity (Per Batch) | Drying Room Size (mm) | Trolleys Number | Trays Number |

| MY-01RD-16L | All-in-one Machine | Up to 100Kg | All-in-one | 16 | |

| MY-01RD-36L | All-in-one Machine | Up to 250Kg | All-in-one | 36 | |

| MY-03RD-60L | All-in-one Machine | Up to 400Kg | All-in-one | 60 | |

| MY-03RD | 1 Unit + 1 Drying Room | Up to 700Kg | 3200*2190*2200 | 8 | 128 |

| MY-06RD | 1 Unit + 1 Drying Room | Up to 1300Kg | 6150*2190*2200 | 14 | 224 |

| MY-12RD | 1 Unit + 1 Drying Room | Up to 2000Kg | 6350*3230*2200 | 20 | 320 |

| MY-15RD | 1 Unit + 1 Drying Room | Up to 2200Kg | 6350*3230*2200 | 20 | 320 |

| MY-03RD (Double) | 2 Units + 1 Drying Room | Up to 1700Kg | 7050*2190*2200 | 16 | 256 |

| MY-06RD (Double) | 2 Units + 1 Drying Room | Up to 2500Kg | 10100*2190*2200 | 24 | 384 |

| MY-12RD (Double) | 2 Units + 1 Drying Room | Up to 4400Kg | 11860*3230*2200 | 40 | 640 |

| MY-15RD (Double) | 2 Units + 1 Drying Room | Up to 5200Kg | 11860*3230*2200 | 40 | 640 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Ray. Ren | Sales Manager

GUANGZHOU MEIYA ELECTRIC EQUIPMENT TECHNOLOGY CO., LTD.

📍 Add: No.217, 2nd Ruiyun Road, Xiuquan Street, Huadu District, Guangzhou, Guangdong, China

📞 Tel/WhatsApp/WeChat: +86 133 4676 7871

✉️ Email: [email protected]

🌐 Website: https://www.my-dryer.com